Subject of thesis:

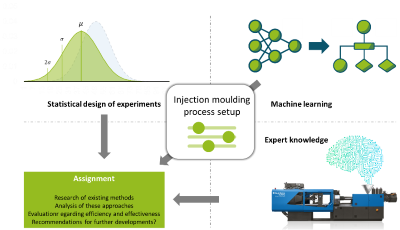

Injection moulding is one of the most complex primary moulding processes in plastics technology. For many companies, the targeted search for suitable setting parameters for the process is particularly challenging. An optimal process point means minimal rejects, high process stability and fast throughput times in operation, which contribute significantly to the achievement of operational goals. For this purpose, either the experience of employees, classical statistical methods or even modern methods of artificial intelligence can be used. Which approach is chosen depends on many different factors.

The work is related to this research project:

The "Internet of Production" (IoP) cluster of excellence at RWTH Aachen University is an interdisciplinary research project in cooperation with 24 institutes and chairs. Within this framework, the IKV Aachen is researching model-based process optimisation, e. g. of injection moulding, to increase process and component qualities. Among other things, a shorter process preparation time for production or an optimisation of the process during production is targeted in the project.

Objective:

At the end of your work, you will have an overview of the type and quality of the methods used in practice for process set-up in injection moulding companies and will be able to make a statement about how companies can develop further, e.g. in the area of Industry 4.0.

Your assignment:

For a bachelor thesis you will work on the following tasks:

- Research practical and scientific approaches to process set-up in injection moulding.

- Evaluation of the efficiency and effectiveness of the approaches in the overall company context

- Preparation of potentials for the further development of companies with different status quo

For a master thesis you will work on the following tasks:

- Research practical and scientific approaches to process set-up in injection moulding.

- Evaluation of the efficiency and effectiveness of the approaches in the overall company context

- Preparation of potentials for the further development of companies with different status quo

- Development of a concrete process template in accordance with DIN EN ISO 9001:2015 to ensure a standardised procedure for the implementation of two previously described set-up strategies AND / OR

- Monitoring and evaluation of the introduction of a new set-up strategy in a company

Your profile:

- Technical or technical-scientific studies

- Basic understanding of plastic injection moulding available at best

- Interest in at least one of the topics mentioned: Process optimisation, programming, Python, quality management, plastics processing, artificial intelligence, Industry 4.0

- Independent and responsible work in addition to supervision

- Reliability and interest in cross-process contexts

- Very good written and spoken German and/or English skills

That sounds like you? Does the thesis topic fit exactly or do you even have your own ideas? Of course you can help to shape the exact topic! Please feel free to contact me to arrange a meeting.

Your contact person:

Yannik Lockner, M. Sc. RWTH

Phone: +49 241 80-96264

E-mail: yannik.lockner@ikv.rwth-aachen.de