Crack growth on a CRP engine hood

Problem: Describe the failure behaviour of CRP

Carbon-reinforced plastics (CRP) are already very widely used in the automotive industry because of their potential for lightweight construction. If suitably designed, the components have, by their very nature, outstanding stiffness. In the individual layers of these often highly stressed constructional elements, any unfavourable orientation or concentration of the forces to be transmitted lead to failure of the composite. This task involved analysing the failure behaviour in testing processes that take into account the specific requirements derived from the application, material and processing.

Methodology: Testing of tear propagation resistance

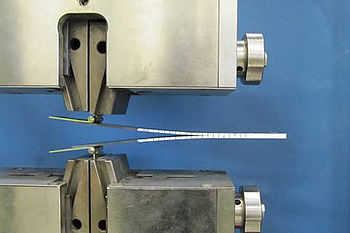

In accordance with the described problem, an analysis was to be made of the separation behaviour of CRP components within the layers. This involved, among other things, determining the tear propagation properties or interlaminar fracture toughness in accordance with ASTM 5528. The specimen is produced as a composite by the defined production process and, if necessary, conditioned in a defined climate. In addition, a defined pre-damage is generated within the layer to be examined.

To adapt the specimen for examination in the universal testing machine, use is made of a device that subjects the composite to the typical tear propagation stress. The laminar failure behaviour of the composite is determined as a function of applied load, duration of the load application and selected load velocity.

Result: Comparable data

Based on these investigations, the aim is to achieve efficient utilisation of the different components over the component as a whole. With this detailed knowledge of the behaviour of the component as a whole in the case of pre-damage, the economic benefit can be optimised.