Electronic components under bending load

Problem: Product testing under realistic conditions

Electronic components on corresponding circuit boards are usually not subjected to great mechanical stress. However, due to new geometries and areas of application, this can no longer be completely ruled out today. Therefore, research is being conducted into new material combinations that can resist high mechanical loads without a loss of electrical functionality. To prove the electrical functionality, on-line tests are carried out in which the product properties are simultaneously monitored under high mechanical load.

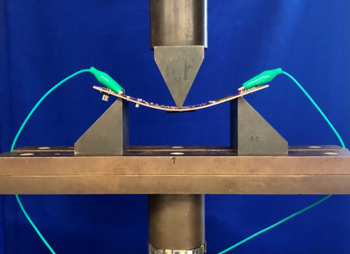

Methodology: Bending tests on circuit boards with electrical conductors

3-point bending tests on circuit boards using a universal testing machine

- Simultaneous monitoring of electrical conductivity

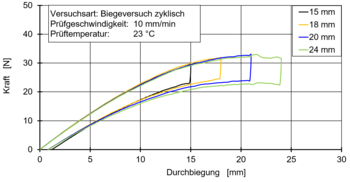

- Recording of the force/deformation curve in a cyclic procedure

Result: No loss of electrical conductivity

The newly developed circuit boards with conductive tracks are characterised using 2 simultaneously running test procedures: The recording of the electrical conductivity during a simultaneous mechanical bending process. Here, a large spectrum of deflections can also be examined in a cyclical process and thus a successive increase in load can be simulated (compare figure left).

The functionality of the components, which is checked on-line by means of special electronics, is always given during the bending tests. Thus, this test set-up can be used within the framework of quality assurance or incoming goods inspection to examine whether the functionality can be guaranteed under a given external mechanical load. In addition to short-term loads, the components can also be subjected to long-term loads. In order to characterise the fatigue behaviour of the electronic component, dynamic-cyclic fatigue tests are suitable.

Your contact for questions