Examination of cracking in returnable PET bottles | Practical example

Examination of cracking in returnable PET bottles

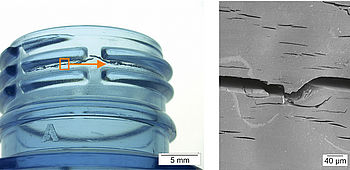

Returnable PET bottles typically pass through twenty or more usage cycles. During washing, filling, transport and storage, plus the actual use by the consumer, the bottles are subjected to a collective load that is different for every bottle. In one case of frequent damage reports, complaints were received from consumers about leaks in the thread area on reusable PET bottles of a specific type.

Method: Simulation tests and microscopic analysis (LIM / FESEM)

- Simulation tests to simulate the life cycle

- The test bottles were marked and, in continuous filling lines, washed, filled, sealed and emptied 10 times.

- Comparative microscopic examinations were carried out to detect possible cracking in relation to the previous filling cycles

Result: Overlapping of effects in the area of the thread

With an increasing number of washing cycles, a rise in the number of visible cracks was observed in the thread area. The cracks were initiated on the outside of the bottles. These cracks do not, however, occur with every returnable bottle, and a correlation was found between crack formation and the design of the cap. With the help of microscopic methods, traces of chemical attack were detected on the surface of the thread. The assumption is that this is due to the effect of the used detergent solution. In addition, orientations/stresses were found in the thread area of the bottles caused by the processing. The cracks were the result of combined tensile and flexural stresses in the thread area due to the prevailing pressure inside the bottle and the cap design. The stress caused by the detergent solution multiplied the effect of the mechanical stresses.

Any questions?

Christoph Zekorn

Microscopic analysis Head of the Microscopic Analysis Laboratory +49 241 80-28341 christoph.zekorn@ikv.rwth-aachen.deDo you have any questions on the subject of microscopy? Then phone us or send a message.