Examination of fuel tanks

Problem: Reduction of the barrier layer thickness in the area of the pinch-off weld

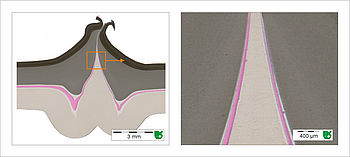

Plastic fuel tanks normally consist of a multilayer PE/EVOH/bonding agent system. The tanks are manufactured by extrusion blow moulding or the half-shell process. Due to the process itself, there is a significant reduction in the barrier layer thickness (EVOH) in the area of the pinch-off weld, as a result of which these areas have a much reduced barrier effect, which can endanger their regulatory approval.

With the aid of a microscopic examination of the EVOH layer in the critical area of the part, the effect of varying process parameters is to be examined in order to subsequently identify an optimum operating point.

Methodology: Microtome cross-sections under selective phase contrast

First of all, a thin layer was produced at room temperature perpendicular to the pinch-off weld. Since the individual layers of the tank wall display hardly any contrast in the thin-layer examination, a selective phase contrast of the EVOH layer was carried out in a dye solution. The hygroscopic property of the EVOH means that it can take up the dye (pink-coloured in the picture). This makes it possible to clearly recognise and quantitatively evaluate the EVOH barrier right down to very thin layer areas.

Result: Weak point in the area of the pinch-off weld

With the help of a software-supported layer thickness measurement and broad parameter variation, it was possible in the bright field to quickly obtain results. As a result, the effect of process parameters on the thickness and quality of the EVOH layer can be shown and the process can be optimised with regard to product quality.

Any questions?

Christoph Zekorn

Microscopic analysis Head of the Microscopic Analysis Laboratory +49 241 80-28341 christoph.zekorn@ikv.rwth-aachen.deDo you have any questions on the subject of microscopy? Then phone us or send a message.