Air-conditioning pipes

Problem: Welding defects on air-conditioning pipes

The air-conditioning for a new building project was designed with plastic pipe systems in hollow floors, suspended ceilings and under plaster. For the whole installation, some 20 km of pipes of different diameters were laid and joined to one another with several hundred welds. Visible faults – especially at the joins (butt and socket welding) – indicated that the work had not been done properly according to the relevant DVS 2202 guideline.

Methodology: Site inspection and microscopic thin-section analysis

- Inspection of the building project, including documentation and sampling of representative welds for laboratory tests

- Preparation of thin sections in the area of the weld joins

- Examination of the thin sections under the polarisation microscope

Result: Inadequate weld quality

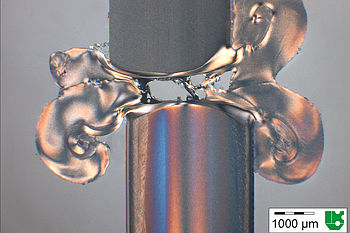

During the inspection of the site it was seen that the pipes not only showed weld misalignment but also in some cases serious angle deviations of up to 10° (permitted: max. 2° according to evaluation group "II"). Over the entire pipe grid there was no marking of the prescribed pipe insertion depth (socket welding). Furthermore, inadmissible deviations in the current installation guidelines were found (installation under mechanical stress / pipe fixing points / creation of compensating bends). The microscopic analysis identified large voids in the joining area, which are characteristic of a poor weld. Adequate weld strength cannot be expected over the long term.

Any questions?

Christoph Zekorn

Microscopic analysis Head of the Microscopic Analysis Laboratory +49 241 80-28341 christoph.zekorn@ikv.rwth-aachen.deDo you have any questions on the subject of microscopy? Then phone us or send a message.