Processing of recyclate material

Problem: Processing of recyclate material

When recyclate of uncertain origin is used, the purity content is frequently unknown. With the aid of a special method for determining its structure and material composition, this uncertainty can be minimised but not always entirely eliminated.

In this particular case, production stoppages occurred at short intervals during the processing of post-consumer polypropylene (PP). The cause was clogging-up of the melt filter. Random analysis of the starting material by infrared spectroscopy did not reveal anything of significance.

Methodology: Combination of morphological, spectroscopic and thermal processes

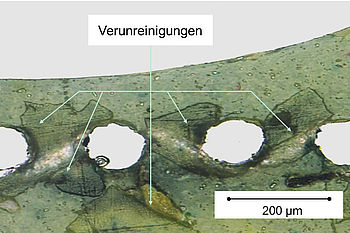

- Morphological analysis of the clogged-up screen (thin section): Impurities in the form of non-plasticised particles

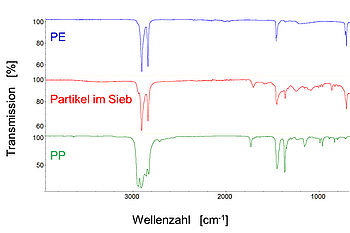

- Analysis of these particles by infrared spectroscopy: Polyethylene in the polypropylene

- Surprising result: The melt temperature of PE is well below that of the PP. Consequently, the PE particles should be plasticisable.

- Thermal analysis of the particles by DSC: The melt temperature (Tm = 135 °C) confirmed the result of the IR spectroscopy. The melt enthalpy was low.

Result: PE crosslinked and not plasticisable

Based on the very low melt enthalpy, the suspicion is that the PE has reacted, as a result of which it was not plasticisable and clogs up the melt filter. Based on these results, it is possible to specifically seek the source of the impurity in the recycling chain and to eliminate the source of the fault.

If the material analysis of the recyclate is carried out too one-sidedly or not consistently, considerable problems can occur during processing. This example shows why a combination of spectroscopic and thermal analysis makes sense.

Any questions?