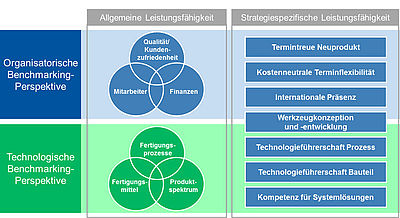

The Institute of Plastics Processing (IKV) in Industry and the Skilled Crafts at RWTH Aachen University, together with Laboratory for Machine Tools and Production Engineering (WZL) at RWTH University, is once again putting together a consortium made up of injection moulding converters with the aim of drawing up a company comparison. The previous benchmarking project of this type was carried out in summer 2014 with a total of seven companies from Germany and Switzerland. The aim is to identify potential for improvement in the participating companies by comparing their performance with that of the others. Performance is compared both from an organisational and from a technological point of view. In this project, IKV's expertise in the field of plastics technology ideally supplements that of the WZL in the field of corporate organisation.

A function-oriented questionnaire developed specifically for the injection moulding segment ensures the comparability of the different data. Answers can thus be given to questions such as "Where does our company stand today", "Where do our strengths lie?", "Where does potential exist for improvement?" and "How efficiently are our resources deployed?"

In addition, by visiting each other's companies, the participants have a chance to see how the "best-in-class" examples actually function in practice in the individual companies. At the same time, the open door offers the hosting company an opportunity to gain honest feedback from industry experts.

On April 7, 2016, IKV and WZL staged an information event in Aachen to enable the participating companies to get to know each other. Further information on this project can be obtained directly via the two university institutes or through the newly established Internet portal, www.kunststoff-benchmarking.de.