The Institute for Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University will again be represented at K 2019 in Düsseldorf from 16 - 23 October 2019 with its own stand in Hall 14/C16. Since the beginnings of the K plastics show in the 1950s, IKV has always taken advantage of this international platform to present some of its key research topics. At K 2019, IKV will present three research projects: Digitalisation in injection moulding, additive manufacturing and plasma coating for particularly small parts.

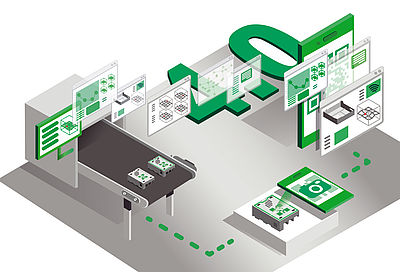

At the focus of the injection moulding project will be a practical demonstration of the digitalisation and optimisation of the production process under conditions similar to those encountered in industry. Increasing process complexity is leading to ever growing challenges in setting up the process. In cooperation with thirteen industry partners, IKV will, with the injection moulding machine up and running, demonstrate a production process that aims to shorten the set-up process through the use of artificial intelligence. The project partners have chosen a housing for the Raspberry Pi single-board computer to serve as the demonstration component.

The additive manufacturing project involves infill structures that represent the internal construct of a component, and largely determine its mechanical properties. The project focuses on the development of a software program for the design of 3D infills to suit the load path. Visitors to the IKV stand at the K show can watch the additive manufacturing of parts with optimised 3D infill structures to suit the load path. The various potential applications of the new 3D infill structures and the results of simulations of different 2.5D and 3D infill structures will be shown.

The team of plasma scientists has developed a modular, highly scalable plasma unit for the interior coating of small hollow articles, such as medical syringes, ampoules, coffee beakers and spouts. Possible functionalities include: increasing the barrier effect against gases and aromas, reducing friction or improving chemical resistance. On the IKV stand, the scientists will demonstrate live the automatic coating of plastic syringes including the handling of specimens. Visitors can compare the friction-reducing effect on coated syringes with that of uncoated ones.

The IKV stand will be located in Hall 14/C16. The Institute's scientists will be on hand to demonstrate the machines in operation and explain the processes.

Contact for the digitalisation project:

Simon Wurzbacher, M.Sc.

Telephone: +49 241 80-93983

simon.wurzbacher@ikv.rwth-aachen.de

Contact for the additive manufacturing project:

Celina Hellmich, M.Sc.

Telephone: +49 241 80-28321

celina.hellmich@ikv.rwth-aachen.de

Contact for the plasma coating project:

Stefan Wilski, M.Sc.

Telephone: +49 241 80-28361

stefan.wilski@ikv.rwth-aachen.de