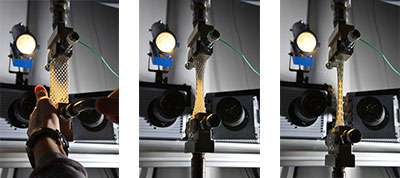

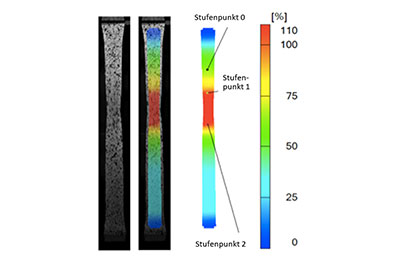

In IKV's Centre for Analysis and Testing of Plastics (KAP), the hydraulically operated high-speed testing machine has been completely reconditioned both electrically and mechanically, and equipped with new control electronics – testControl II, from the firm ZwickRoell. Using the now time-triggered ARAMIS 3D high-speed camera system from the firm GOM, the correlation of strain value pairs with the machine data can now be automated even at high scanning rates.

Material data for crash simulation and under crash-like loads can thus now be determined under state-of-the-art conditions. Apart from the optical strain measurement, temperature ranges from -40 °C to 100 °C can be covered so that the materials can also be characterised in terms of their temperature dependence. In addition to a broad velocity spectrum (0.01 m/s to 12 m/s), the apparatus also has a high resolution in the force signal range from 100 N to 20 kN. This means that plastic film, knitted and woven fabrics, foamed plastics, fibre-reinforced plastics and the many thermoplastics can all be characterised as a function of strain rate. The use of the high-speed camera system can frequently help to visualise failure processes because the processes occurring in a crash are unperceivable for the human eye.

Following completion of this modernisation, the equipment can be used not only to carry out the common material data measurements at different temperatures, but also to embark on a new research project to validate this new system on FRP materials under shear stress.

Your contact for questions on this subject:

Dipl.-Ing. (FH) Christiane Wintgens

Phone: +49 241 80 - 28342

E-Mail: christiane.wintgens@ikv.rwth-aachen.de