The corona pandemic is presenting medical care with enormous challenges even in highly developed countries. In developing countries, the conditions could well become catastrophic. Against this background, staff members, colleagues and former students of RWTH Aachen University have come together under Prof. Dr.-Ing. Dr. med. Steffen Leonhardt to develop a ventilator that is suitable for the medical treatment of COVID-19 patients in intensive care units over a period of several weeks. This initiative supplements the numerous other projects and equipment targeted at short-term emergency care – for example, as needed on the way to hospital. The PV1000 device is being developed in cooperation with intensive care medical staff at the Aachen University clinic, and takes account of approval-related aspects. To finance and manufacture the devices (which are being provided free of charge to hospitals in emergency regions), the non-profit company AC4Health was founded, which, with immediate effect, welcomes contributions in the form of donations, components and offers of cooperation.

The COVID-19 disease is creating a large number of supply bottlenecks around the world, motivating more and more people to help ease the suffering through voluntary commitment. For example, five weeks ago, numerous members of staff from the Chair for Medical Information Technology (MedIT), the Chair for Informatics 11, the Chair for Medical Technology (mediTEC), the Institute of Automotive Engineering (ika) and the spin-off company fka GmbH joined up with two experienced developers of ventilators, Professor Steffen Leonhardt und Dr. Marian Walter. They all share the common aim to make a life-saving contribution to mastering this global medical challenge by developing and manufacturing a ventilator for intensive care.

IKV's involvement in the project

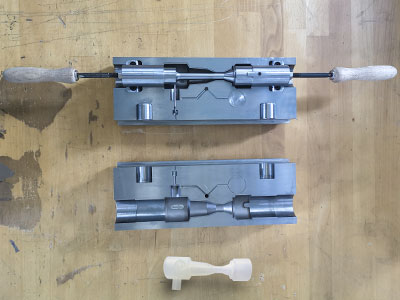

The Institute for Plastics Processing (IKV) is participating in the project by manufacturing various complex components. At IKV, for example, the final selection of materials was made for the prototype production and a new insert was designed and produced for an injection moulding tool. The first prototypes were sampled on one of the Institute's injection moulding machines, and these components have now been made available to ika for further tests. In addition, the IKV staff will design a non-return valve made of a thermoplastic material and produce a mould insert for connecting to the silicone component. A prototype of PTFE has now been produced. The component is located in the expiratory part of the ventilator. For the non-return valve, a membrane is also being developed to ensure one-way air flow.*

Other project partners

The Institute for Fluid Power Drives and Systems (IfAS) is cooperating in a consulting capacity. Also participating is the Clinic for Surgical Intensive Care and Intermediate Care (OIM), advising on matters of medical practicality and testing. Operational support is being given by Mindmotiv GmbH (testing) and SurgiTAIX AG (quality management) to ensure maximum possible maturity of the ventilator.

The intensive voluntary work, also at week-ends, has paid off: For all the relevant modules of the PV1000 ventilator, at least one technical variant has been built and tested, which means that the entire concept can now be specified, also taking account of the availability of critical components.

The project is thus entering the operative phase because the specifications can now be finalised, components procured, and the actual device finally designed and built. For this purpose, the company AC4health gUG was established last Thursday, complying with the strict criteria of a non-profit organisation and allowing production of the device on the basis of donations and contributions. In the first step, 1,000 ventilators are to be produced and transported with political or private support to affected regions.

Further information on this humanitarian project can be found at: www.pv1000.de

Project partners:

- Chair for Medical Information Technology (MedIT) at the Helmholtz Institute for Biomedical Technology RWTH Aachen University

- Institute for Automotive Engineering (ika) at RWTH Aachen University

- Chair for Informatics 11 – Embedded Software RWTH Aachen University

- Institute for Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University

- Chair for Medical Technology (mediTEC) at the Helmholtz Institute for Biomedical Technology, RWTH Aachen University

- fka GmbH Aachen

- Mindmotiv GmbH

- SurgiTAIX AG

- WickedNet

- Christian Laczny – UI / UX Design

*IKV would like to sincerely thank F+E Formenbau + Entwicklung GmbH for its support with the production of the mould insert as well as Momentive Performance Materials GmbH and Mitsui Chemicals Europe GmbH for donating the material.

Contact partners for inquiries:

Anneke Schultz

AC4health gUG

E-Mail: presse@pv1000.de

Michael Drach, M.Sc.

Kautschuktechnologie am IKV

Tel.: +49 241 80-28353

michael.drach@ikv.rwth-aachen.de