Materials Technology

Analysis and modelling of the behaviour of plastics

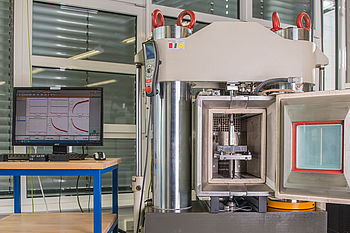

Understanding the complex behaviour of plastics is an essential requirement for the successful design of plastic parts and processing processes. The properties of the material are not defined until the processing stage.

We carry out research in the field of materials technology with the focus on the following aspects:

- the influence of the material's components (e.g. additives, fillers),

- the inner structure of the material (e.g. fibre orientations, crystalline structure),

- the design and stresses affecting the material during use (e.g. in relation to time, temperature).

Aim of our research and development activities

The aim of our research and development activities is to analyse and model the behaviour of the material with regard to its suitability for a particular application. From this, we derive reliable data for a realistic prediction – i.e. related to the material and the load – of the part properties within the context of virtual product development. We model processing processes with the aim of contributing to process and mould design by simulation, and of simulating and specifically adjusting the processing-dependent material behaviour in the part.

Our focus is on thermoplastics and thermoplastic elastomers, thermosetting plastics and elastomers. Material combinations such as cohesive plastic/metal hybrids are also a subject of research.

Ongoing research projects in the field of materials technology

- Modelling of the visco-elasto-plastic material behaviour of thermoplastic elastomers (TPE)

- Testing and development of materials for the industrial producibility of customised large plastic parts through large-area additive manufacturing

- Description of the direction-dependent structure-borne behaviour of short glass fibre-reinforced thermoplastics

- Infinite service life for high-performance materials

- Material data optimisation for the improved prediction of shrinkage and warpage in injection moulding simulation

- Accelerated service life testing of short glass fibre-reinforced thermoplastics

- Modelling and testing of the crash behaviour of plastic/metal hybrid joints

- In-situ measurement of the melt temperature in injection moulding with ultrasonic tomography

- Modelling of the mechanical behaviour of long fibre-reinforced thermoplastics (LFT)

- Multi-scale simulation of the solidification of semi-crystalline thermoplastics

- Delfin – Research into alternative materials and production processes for cost and weight-reduced pressure vessels of continuous fibre-reinforced plastic

Events in materials technology research

Latest news from this research area

Your contact partner for questions on materials technology research

Hakan Çelik, M.Sc.

Head of department Structure Calculation and Materials Technology +49 241 80-28359 hakan.celik@ikv.rwth-aachen.deDo you have any questions regarding this area of research? Then I look forward to your call or message.