SFB-TR 87

Pulsed high-power plasmas for the synthesis of nanostructured functional layers

Thanks to continuously improved plasma processes, packed products are becoming more durable, mobile phones are getting smaller and computer performance is increasing. This success is mainly subject to the close link between plasma diagnostics and process technology, and to in-situ monitoring of process-related parameters and their correlation with the structures obtained. These are the major subjects of the SFB-TR87 collaborative research centre that concentrates expert knowledge in the areas of plasma physics, plasma technology as well as materials science and surface technology. Experts from RWTH Aachen University, Ruhr University Bochum and Paderborn University investigate barrier systems with unique tribological properties on metal substrates in addition to barrier properties on plastics substrates.

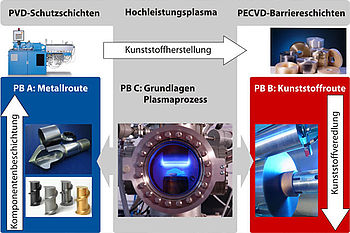

The SFB-TR 87 project includes a „metal route“ mainly concerned with PVD coatings on components in plastics processing machines. The “polymer route” benefits from know-how in the fields of plasma and process technology as well as materials science to equip plastics for barrier applications by means of PECVD coating. Elementary knowledge of plasma processes (project area C, “elementary principles”) form the basis of methods development in the SFB-TR 87 research project. What all three routes have in common is their target of reaching a fundamental understanding of the mechanisms on the synthesis route towards high-power plasma coating, in order to predict these processes.

Target of SFB-TR 87 research

In order to reach a profound understanding of the mechanisms on the synthesis route to high-power plasma layers, the latest source technology is applied, some parts of which were developed by the scientists themselves. The source technology is characterised using a vast range of quantitative plasma diagnosis methods, some of them new as well. This is done by modelling and one-time experiments on single particles. Another aim of the investigations is to learn about the inter-relations between material properties and plasma parameters, and to benefit from this knowledge in the areas of plasma control, layer development and in-situ layer control. This way, researchers can overcome the usual empiric proceeding and develop a process understanding based on physical and chemical knowledge.

IKV works on the following sub-projects:

IKV research within sub-project B1 of SFB-TR 87 is focussed on two targets. One aim is to investigate and describe the inter-relations between the morphologies and functionalities of large-surface plasma polymer coatings and the respective plasma processes. The other aim is to transfer this basic knowledge on coating processes to large-surface plastics substrates and make it serviceable for application. For this purpose, nanostructured functional layers to improve gas barrier properties (in particular O2, H2O) are deposited on polymer materials (polyethylene terephthalate (PET), propylene (PP)). Layers at IKV are developed right on large-surface substrates, while layer systems from other sub-projects are upscaled. This sub-project is therefore the interface between fundamental layer development and large-surface application.

Subproject B1: Plasma-assisted barrier coating of flexible plastics based on the examples of polyester and polypropylene

Subproject B1 in phase 3

The scalability of the processes from project B of Trans-regional Collaborative Research Centre 87 (SFB-TR 87) and its transferability to new applications are at the focus of subproject B1 in phase 3 of this SFB.

The plasma reactor LAMPS (Large Area Microwave Plasma System) was developed and set up at IKV in the first phase of SFB-TR 87 with the aim of homogeneously synthesising large-area layers. In the second funding period, the gas distribution system of the reactor, supported by a simulation of the neutral gas distribution in cooperation with C8, was further developed and a significant homogenisation of the layer properties was achieved. The studies also showed the clear influence of the energy input on the homogeneity of plasma and layer, which will be the subject of the investigations in phase 3.

The plasma reactor LAMPS was equipped for this purpose in phase 2 with a microwave tuning system in order to have better control of the energy input and thus be able to examine its influence on the homogeneity of the plasma properties and the local form of the layer properties in cooperation with B3 (ellipsometry), B2 (PAP), B4 and C1 (MRP, Langmuir) as well as C2 (layer tension). The results are linked with the simulation of the used MW plasmas with the focus on the plasma process parameters and the resulting ion energy distribution functions in C4.

In this subproject, use is made of two innovative analysis methods that make it possible to monitor and measure the plastic layer system property of layer tension as well as the process temperature during the coating process. The use of these methods allows a direct correlation of these parameters with the resultant plasma and layer system properties and thus extends the spectrum of controllable plasma parameters for the specific setting of layer system properties.

As part of the studies on the transferability of the models and layer systems from SFB-TR 87, use is made of innovative substrate materials and geometries: By deploying, as the substrates, plastics that have high permeability, it is aimed, in cooperation with B7, to produce coatings with defined release properties that can be used as a membrane. A cup geometry is used as the substrate geometry in order to examine, in cooperation with B4, the transferability of the obtained models and layer systems of flat substrates to more complex geometries. This involves, among other things, developing a method for the spatially resolved measurement of the plasma properties in complex geometries and simulating the neutral gas distribution in the reactor in C8, and also simulating the MW plasmas in C4, this time in each case incorporating the cup geometries in the reactor LAMPS.

In addition to this, in cooperation with B3, A1, A3, A6, A7, C1, C6, C7 and C8, the transferability to plastic substrates of the layer systems developed for metal substrates in project area A as part of SFB-TR 87 will be studied for the first time. B1 will undertake in this context the production of specimens by injection moulding and the examination of system properties.

Publications:

(1) H. Behm, K. Bahroun, H. Bahre, D. Kirchheim, F. Mitschker, N. Bibinov, M. Böke, R. Dahlmann, P. Awakowicz, Ch. Hopmann, J. Winter: Adhesion of Thin CVD Films on Pulsed Plasma Pre-Treated Polypropylene. Plasma Processes and Polymers 11 (2014) 5, S. 418-425 (B1, B2, B4, B5)

(2) H. Bahre, H. Behm, D. Grochla, M. Böke, R. Dahlmann, Ch. Hopmann, A. Ludwig and J. Winter, “Film stress of amorphous hydrogenated carbon on biaxially oriented polyethylene terephthalate“, Plasma Process. Polym., (2015), 896-904, doi: 10.1002/ppap.201500045 (B2, B1, C2)

(3) A. Bulusu, S. Graham, H. Bahre, H. Behm, M. Böke, R. Dahlmann, Ch. Hopmann, and J. Winter, “The mechanical behavior of ALD-polymer hybrid films under tensile strain“, Adv. Eng. Mater. 17, (2015), 1057, doi: 10.1002/adem.201400431 (B2, B1)

(4) D. Kirchheim, M. Jaritz, R. Dahlmann, Ch. Hopmann: Wirkmechanismen bei der Barriereausrüstung von Kunststoffen mit Hilfe von PECVD. Vakuum in Forschung und Praxis (2016)

(5) Ch. Hopmann, R. Dahlmann, C. Windeck, D. Kirchheim: Barriereverbesserung für Folien durch dünne PECVD-Multilayer. 28. Internationales Kolloquium Kunststofftechnik. Aachen, 2016, ISBN:978-3-8440-4033-3

(6) M. Jaritz, H. Behm, D. Kirchheim, F. Mitschker, R. Dahlmann, Ch. Christian, P. Awakowicz: Influence of UV- and VUV-radiation of argon- and oxygenplasma pretreatments on the interface of PECVD-coatings and polypropylene (Hochgeladen; Article reference: JPhysD-109481)

(7) F. Mitschker, S. Steves, M. Gebhard, M. Rudolph, L. Schücke, D. Kirchheim, M. Jaritz, M. Brochhagen, C. Hoppe, R. Dahlmann, M. Böke, J. Benedikt, I. Giner, T. de los Arcos, Ch. Hopmann, G. Grundmeier, A. Devi, P. Awakowicz: Analysis of Coating Defects in Permeation Barrier Films deposited on PET. Plasma Processes and Polymers (Hochgeladen)

(8) H. Behm, M. Jaritz, D. Kirchheim, R. Dahlmann, Ch. Hopmann: Influence of a substrate bias on the adhesion of silicon organic PECVD-films on polypropylene. ANTEC 2015 - Proceedings of the Technical Conference & Exhibition. Orlando, USA, 2015

(9) D. Kirchheim, K. Bahroun, H. Behm, M. Jaritz, F. Mitschker, P. Awakowicz, R. Dahlmann, Ch. Hopmann: Influence of Intermediate Layer Type and Thickness and Barrier Properties of Multilayer PECVD Barrier Coatings on PET. ISPC 22nd International Symposium on Plasma Chemistry, Antwerpen, Belgium, 09.06.2015

(10) D. Kirchheim, M. Jaritz, R. Dahlmann, Ch. Hopmann: Barrieren ohne Grenzen. K-Zeitung, 07.08.2015

In this subproject, a multi-scale simulation method is to be established to establish the proportion of the pore-dominated mass transfer through plastics with PECVD coatings and in particular to quantity it. The pore distributions are determined experimentally with the oxygen etching process and supplemented with methods for determining the total volume of the pores (B3, B7). This enables conclusions to be drawn about the size distribution of the nano-scale pores and the weighting of the individual amounts. The simulation incorporates both continuum-mechanical approaches and semi-classic atomistic methods of molecular dynamics.

In this transfer project, the IKV team, in cooperation with an industry partner, aims to develop suitable coating systems that can resist the cleaning process with caustic soda in the multi-use process.

Any questions on this research programme?

Prof. Dr. rer. nat. R. Dahlmann

Scientific director Circular economy Head of the Centre for Analysis and Testing of Plastics +49 241 80-25928 rainer.dahlmann@ikv.rwth-aachen.deThis programme is promoted by