Process development

We help you develop economical and robust manufacturing processes

The possibilities available at IKV for simulating process chains make us a valuable partner in the field of process development. Our pilot plants and technical laboratories contain all kinds of injection moulding machines, handling systems, extrusion lines, forming machines, presses, winding units and pultrusion machines.

We produce samples, prototypes and small-series products of:

- thermoplastics

- thermosetting plastics

- elastomers

- polyurethanes

- fibre composites

- foams

We support you in your process development

Prof. Dr. rer. nat. R. Dahlmann

Scientific director Circular economy Contact for cooperations in research and development +49 241 80-25928 rainer.dahlmann@ikv.rwth-aachen.deWe are ideally equipped to develop new processes

Injection moulding

- Electrical and hydraulic machines

- Clamping forces from 6 t to 240 t

- Dynamic mould tempering

- Physical foaming (MuCell/ProFoam)

- Fluid-assisted injection moulding

- Mould technology

- Modern sensor technologies

- Filling simulation

Extrusion

- Profile and film extrusion

- Blow moulding, stretch blow moulding, thermoforming with process simulation

- Thermoplastic and elastomer foaming

- Inline viscometry

- Simulation of the flow behaviour of melts and foams

- Design of extrusion dies

Fibre composites

- Resin Transfer Moulding

- SMC compression moulding

- Processing of thermoplastic FRP

- Pultrusion

- Filament winding

- Processing of long-fibre-reinforced thermoplastics (LFT)

- Process and product simulation

Elastomer processing

- Extrusion and injection moulding

- Foaming, 2K

- Optimisation of vulcanisation

- Material modelling and product design

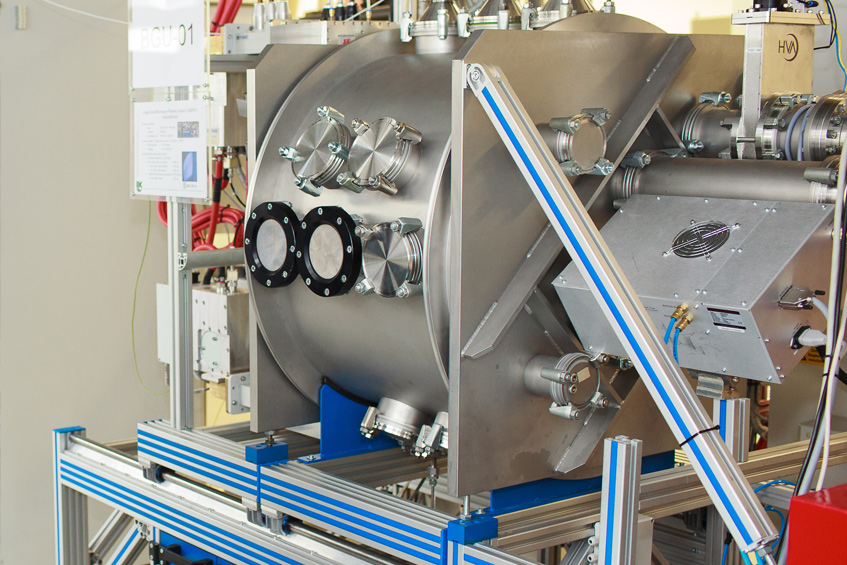

Surface technology

- Coating and process development (e.g. barrier, scratch resistance)

- Adapting the process to substrate properties / feasibility analyses

- Process control / quality assurance

- Surface analysis

Joining technology

- Material and process selection for all applications and joining processes

- Ultrasonic welding

- Laser transmission welding

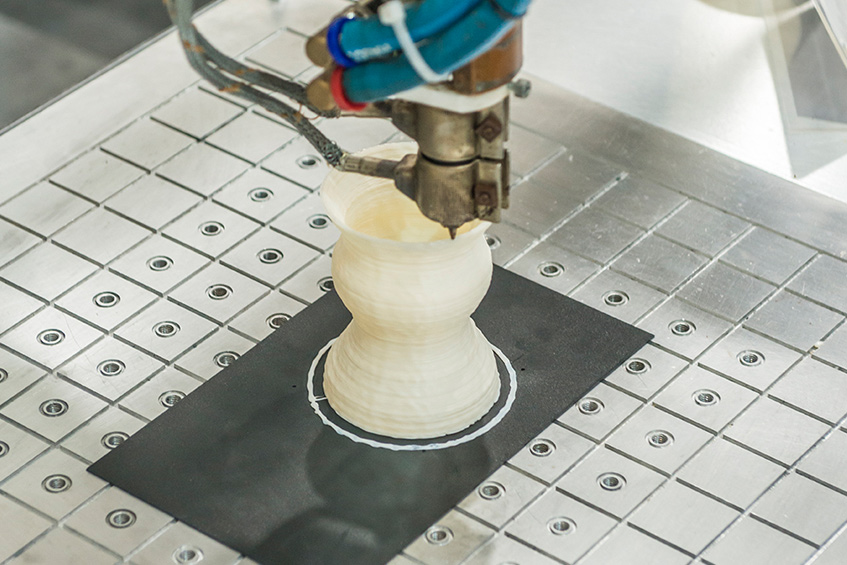

Additive manufacturing

- Material-related part properties

- Process analysis and modelling

- Hybrid production

- Cyber Physical Production System (CPPS)