Material Development

We support you in the development of materials for your products

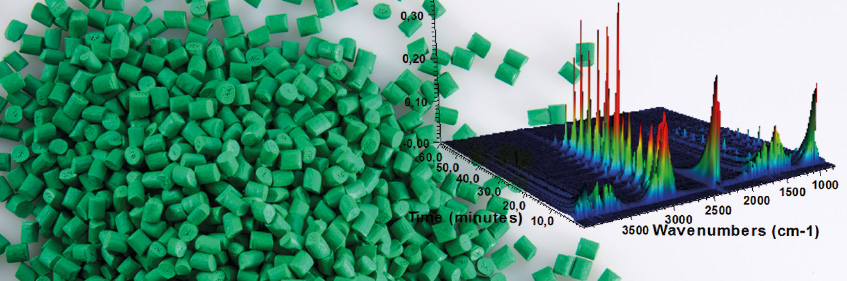

Innovations are very often linked to material developments. Plastics offer an infinite number of possibilities here, for example through modification of the polymer structure, the use of additives or the addition of fillers or reinforcing materials.

We support you with materials development, e.g. by:

- Compounding blends and additives, fillers and reinforcing materials

- Analysing the attained material properties

- Testing the practical suitability for processing (extrusion, injection moulding, RIM, forming, joining etc.)

- Developing and producing samples to suit the material and/or required load, and devising test methods (static load, creep/relaxation, crash or fatigue)

- Evaluating, selecting and calibrating material models for process and part simulations in FEM

- Modelling the mechanical behaviour, material damage and failure

- Drawing up material maps by comparing simulation and experiment (reverse engineering)

- Analysing ageing/fatigue under environmental influences (e.g. temperature, media, UV, mechanical stresses)

- Measuring surface functionalisation by plasma processes

- Undertaking material-related selection of suitable joining processes

We support you in material development

Prof. Dr. rer. nat. R. Dahlmann

Scientific director Circular economy Contact for cooperations in research and development +49 241 80-25928 rainer.dahlmann@ikv.rwth-aachen.deWe exhaust development potential

- Thermoplastics

- Elastomers

- TPE

- PU

- Thermosets

- FRP