Evaluating product quality

We assess the quality of plastic products

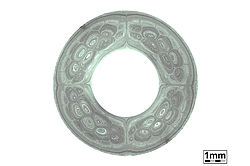

The quality of a plastic product is very sensitive to any influencing factors during its production. Even minor errors in designing the product or mould and wrong processing parameters such as process temperatures and pressures can result in inferior product quality that cannot be detected with the naked eye or with normal methods of quality control. Here tomographic, microscopic, spectroscopic and thermal analysis methods can be deployed to quickly expose the "inner values". One example is this micro-section of a press stud (see photo), which shows product weaknesses stemming from its processing. It also helps with making improvements that can often be implemented at little cost.

The above-mentioned methods may also be supplemented by mechanical testing processes, especially when relevant product specifications exist.

Prof. Dr. rer. nat. R. Dahlmann

Scientific director Circular economy Head of the Centre for Plastics Analysis and Testing +49 241 80-25928 rainer.dahlmann@ikv.rwth-aachen.deMy team and I are always ready to answer your questions. Just call us or send us a message.