Testing and analysis methods at the KAP

Find out more about our extensive equipment

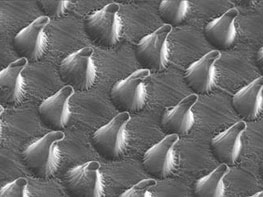

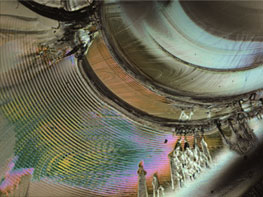

Microscopic analysis

Microscopic techniques offer specific examination options for plastics analysis, not only as part of research and development activities but also in particular for damage analysis and quality assurance. They include:

- Determination of material properties

- Identification of processing defects for evaluating part quality

- Fractographic examinations

- 3D-visualised surface quantifications

- Description of internal stresses and orientations with a polarisation microscope

- Evaluation of the design characteristics of a component

- Quantification of the amount and distribution of fillers and reinforcing materials, pores and multi-phase systems

- Volume-based component measurements and structural examinations

The microscopic preparation and analysis processes available at IKV cover the entire range that is of relevance for plastics analysis, with a view to obtaining meaningful results quickly and reliably. Of key importance here is the preparation of the specimen. The Institute possesses a broad knowledge base for obtaining reliable test results within the shortest possible time due, not least, to its day-to-day involvement in public research projects and the time it spends dealing with wide-ranging questions from industry.

Equipment and contact person

- Light macroscopy

- Light microscopy

- Scanning electron microscopy

- Energy-dispersive X-ray spectroscopy

- Transmission electron microscopy

- Atomic force microscopy

- Laser confocal microscopy

- µ-computer tomography (µ-CT)

- Microscope heating and heating/shearing tables

- Preparation equipment (precision wet cutting machine, automatic sanding and polishing machines, microtomes, ultra-microtomes, …)

Christoph Zekorn

Microscopic analysis Head of the microscopic analysis laboratory +49 241 80-28341 christoph.zekorn@ikv.rwth-aachen.deSpectroscopy

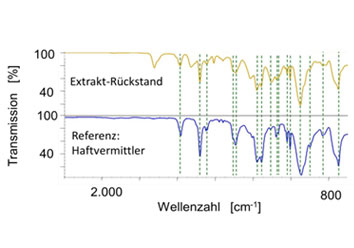

In many applications, precise identification of the material serves as the basis for the subsequent work steps and processes. Not only plastics but also a number of other organic and inorganic substances can be identified with the following methods, which are indispensable aids for structure clarification:

- Fourier transform infrared spectroscopy (FTIR) is in most cases a non-destructive standard process for the identification of (semi-)organic substances and thus also of plastics, coatings and contamination.

- To characterise inorganic substances such as fillers, one option is to use energy-dispersive X-ray structural analysis (EDX). This form of near-surface elementary analysis (≥ atomic number 6) can be performed either at a specific point or over a defined area.

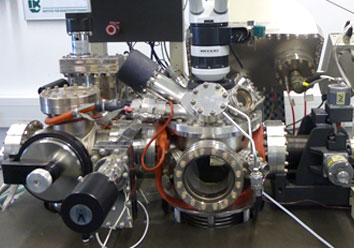

- Using electron spectroscopy for chemical analysis (ESCA) – also known as X-ray photoelectron spectroscopy (XPS) – an elementary analysis (≥ atomic number 3) of the surface and thus of the first few nanometres is carried out.

The following tasks can typically be performed with spectroscopic methods:

- Material identification

- Quality control

- State of ageing / oxidative damage

- Identification of contamination

- Measurement of reaction kinetics

- Surface analysis including barrier and protective coatings

- Trace analysis of metal compounds such as metal oxides, including their distribution

Equipment and contact person

- Fourier transform infrared spectroscopy (FTIR)

- Electron spectroscopy for chemical analysis (ESCA or XPS)

- Energy-dispersive X-ray spectroscopy (EDX)

- Coupling with thermal analysis in the form of TGA/DSC/FTIR/MS

Dr. rer. nat. Sabine Standfuß-Holthausen

Spectroscopy Head of the spectroscopy laboratory +49 241 80-28346 sabine.standfuss-holthausen@ikv.rwth-aachen.deMechanical testing

Mechanical testing is an important tool for product testing and quality assurance. To describe the mechanical properties of construction materials, testing methods such as tensile tests, notched flexural impact testing and hardness testing are fundamental and frequently used methods. The deployment of universal testing machines allows both standardised testing processes and individual component tests.

As examples, here are some of the test methods carried in our laboratories in the course of accelerated testing:

- Tensile, compression, flexural tests

- Torsion pendulum tests, shear tests

- Crack expansion tests, tear propagation tests

- Bonding strength tests

- Friction tests

- Determination of compression set

Additional external influences on the plastic such as climate and media have to be taken into account at the test planning stage and when preparing the specimens. The mechanical tests are frequently preceded by sample preparation, ageing by UV radiation and weathering in conditioning cabinets.

Furthermore, some areas of the laboratory are ideally equipped for various long-time and dynamic tests. Throughout the laboratory, testing is carried out on thermoplastics thermosets and fibre composites.

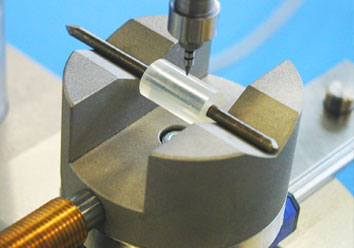

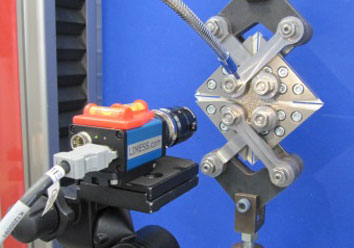

Equipment and contact person

- Specimen production

- Specimen conditioning

- UV and conditioning chamber

- Universal testing machines for accelerated testing (including effects of climate and media)

- Dynamic testing machines (fatigue tests)

- Long-term test benches

- High-speed tensile testing and penetration testing machine

- Drop tower

- Pendulum

- Abrasion testing device

- Rebound testing device

Tobias Conen, M.Sc.

Mechanical testing Head of the mechanical testing laboratory +49 241 80-28345 tobias.conen@ikv.rwth-aachen.deThermal analysis

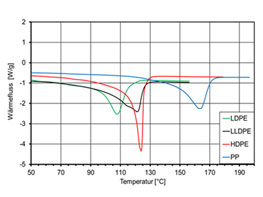

The many different thermal analysis methods provide valuable assistance in recognising complex relationships between the processing, structure and properties of the plastics. By means of thermal analysis, polymers can be identified and characterised, and the influences of processing and material damage can be detected.

Many properties that are key for the processing and use of plastic products can be determined in this way, including:

- Melt temperature, melt enthalpy

- Solidification temperature

- Glass transition temperature

- Crosslinkage states with thermosetting plastics and elastomers

- Qualitative and quantitative description of thermal and thermo-oxidative degradation processes

- Determination of filler and reinforcing agent contents

- Expansion coefficients

- Internal stresses

- Temperature-dependent elasticity moduli under all kinds of different loads

The methods are used for a wide variety of different materials, e.g. thermoplastics, thermosetting plastics, elastomers, resin and adhesive systems, foodstuffs, pharmaceuticals, building materials, etc. etc.

Equipment and contact person

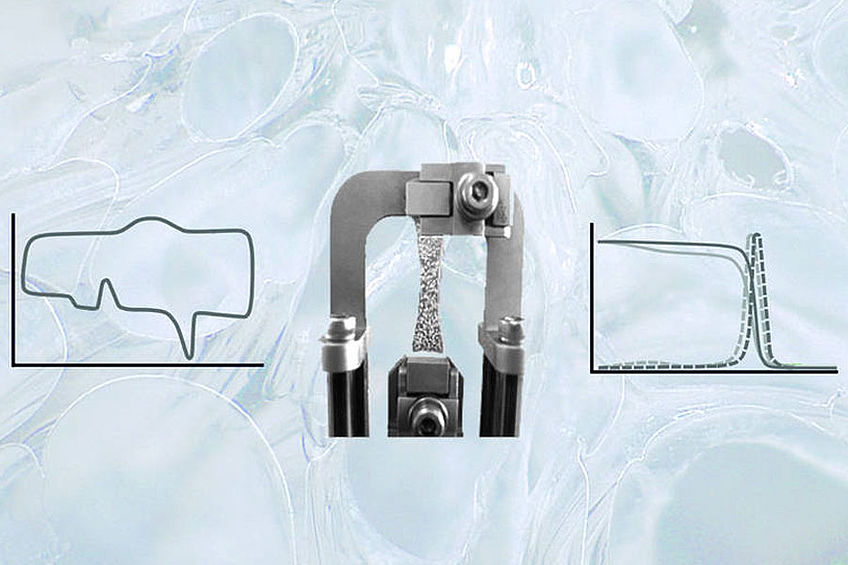

- Differential scanning calorimetry (DSC)

- Thermogravimetric analysis (TGA) with coupling options with FTIR and MS

- Thermomechanical analysis (TMA)

- Dynamic-mechanical analysis (DMA)

Meike Robisch

Physical analysis Head of thermal analysis laboratory +49 241 80-27319 meike.robisch@ikv.rwth-aachen.deRheometric analysis

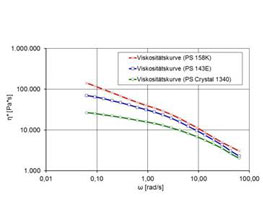

Knowledge of the flow behaviour of plastic melts and rubber or silicone materials and information on the viscosity of resin systems is essential to be able to accurately design the processing processes. Apart from determining the actual viscosity, it is also possible to measure their elastic and viscous proportions. This yields, for example, important information on the extent to which a plastic melt reacts to shear loads through a rise in temperature. Since the viscosity of a plastic is the product of many individual properties (molecular weight distribution, degree of branching, additives), it is also possible with rheometric methods to detect batch fluctuations on a comparative basis.

The following properties can be described with the aid of rheometric tests:

- Viscosity as a function of temperature, shear rate and pressure

- Elastic / ideal viscous proportions of the viscosity

- Pseudoplasticity

- Determination of Carreau parameters

- Storage modulus and loss modulus as a function of temperature and shear rate

- Change in a molecular structure (e.g. through degradation or crosslinkage)

- Change in the additive content

- Gel point and/or pot life of a resin system

Especially oscillatory measurements offer a large number of possibilities for describing materials. For this, preliminary trials are necessary to find a suitable individual operating point of the interaction system between rheometer and material.

Equipment and contact person

- Capillary rheometer

- Rotary rheometer

- Mel index device

- Mooney viscometer

- Rubber process analyser

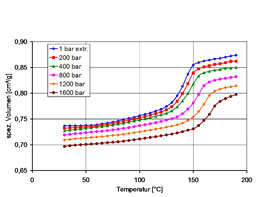

Physical analysis

Determining physical properties and material characteristics is of major importance in plastics analysis whenever process design and/or process parameters are involved. Furthermore, this information serves to give a deeper understanding of the material, which is necessary above all for predicting its behaviour in later application. Thus the physical properties of a material to be processed such as its shrinkage behaviour and (residual) moisture provide important information about the polymer and about the reactive systems. With regard to targeted application possibilities, factors such as thermal conductivity and barrier properties play a major role. In other circumstances, the focus could be on such properties as the wetting behaviour in contact with hydrophilic/hydrophobic media, or on colour and gloss differences.

Examples of some physical properties are:

- Moisture content

- Density

- Thermal conductivity, temperature conductivity

- Shrinkage behaviour

- Transparency and opacity effects

- Colour and gloss differences

- Water vapour and oxygen permeability

- Wetting properties

Also in the field of failure and damage analysis, a determination of the physical properties of a part and/or the starting material can contribute to clarifying the failure or the cause of failure.

Equipment and contact person

- Karl-Fischer Titration (KFT),

- Turbidity and gloss measurement

- Colour measurement

- Contact angle measurement

- Pyknometry

- PVT measuring device

- Water vapour and oxygen permeation measuring devices

- Various methods for measuring thermal conductivity (PVT, transient plane source method (TPS), plate-plate apparatus and LFA)