Centre for Analysis and Testing of Plastics (KAP)

We deploy our experience for your benefit: Analysing, testing, consulting, improving

Problem solutions from a single source

When correctly deployed, plastics analysis and testing are vital tools when it comes to describing the state of a material. With the aid of an expertly devised analysis, it is usually possible to take a plastic product and deduce the type of material used, the quality of the processing and the conditions it has experienced in use. Through suitable tests, the material data can be identified for subsequent product and process development. This is invaluable for product quality, product reliability and product safety in every respect.

Experience is key here. And you can benefit greatly from combining your experience with ours. In this way it is possible to quickly gain valuable information on material and process development, product testing, quality assurance, and systematic failure and damage analysis.

Test and analysis methods

About the KAP

The Centre for Plastics Analysis and Testing (KAP) can call on extensive and modern equipment for testing the mechanical, physical, chemical and morphological properties of plastics. Coupled with our experience in materials science and processing technology, we are in a position to offer comprehensive support very quickly on all problems concerned with plastics technology.

Physicists, chemists, engineers, technicians and material testers form an interdisciplinary team at the KAP, which is entirely familiar with the diversity of issues arising in this field. This means we are in a position to support our customers over a broad spectrum. Customer orientation and individually adapted systematic procedures ensure objective and targeted working.

We work with customers from different industries

- Automotive

- Construction

- Electrical and electronics

- Medical technology

- Packaging

- Other sectors and projects

We advise you comprehensively and individually

Prof. Dr. rer. nat. R. Dahlmann

Scientific director Circular economy Head of the Centre for Plastics Analysis and Testing +49 241 80-25928 rainer.dahlmann@ikv.rwth-aachen.deMy team and I are always ready to answer your questions. Just call us or send us a message.

You can take advantage of our service

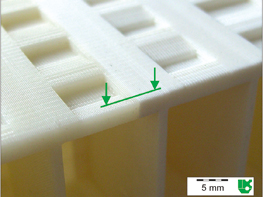

In the event of acute problems, we offer our industry partners a structured and comprehensive damage management system. The first step is always a systematic damage analysis of the defective plastic product. Once the cause has been identified, we advise our customers in detail and on an individual basis. This makes it possible to minimise subsequent damage and prevent a recurrence of the problem.

Good reasons to use our service

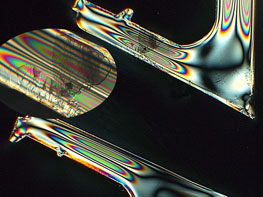

The benefits of systematic failure and damage analysis are obvious: Only if we identify the defects and failures of the past and analyse their causes can we take preventive measures to minimise the relevant faults in present and future products. However, tracing a defect or failure to its cause(s) is frequently a complicated process because the possible influences are many and varied, and may well have occurred a long time ago. Using our systematic procedure for failure and damage analysis, we will be pleased to support you in solving your individual problems.

In the form of a neutral, trustworthy and independent consulting system, we will be pleased to support you in finding an explanation for cases of damage by going through the problem together with you, discussing the implications, developing the possible causes of the damage, and, after consulting you, defining the necessary analyses. With the help of the results, we can formulate possible solutions and derive measures to eliminate the faults. We can also discuss this with you personally if you wish.

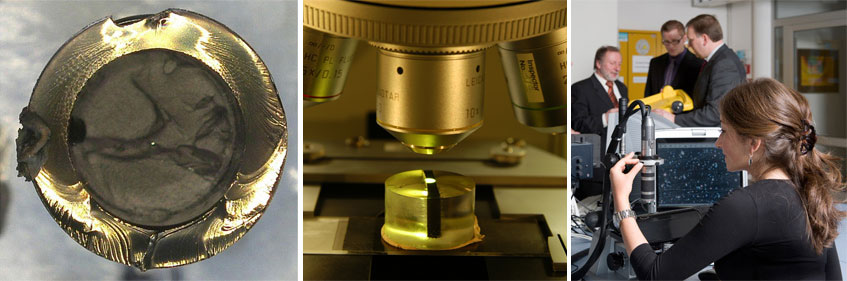

With over 700 square metres of laboratories at their disposal, our qualified staff have all the necessary relevant testing and analysis equipment to tackle your questions on data measurement, part testing and damage analysis. We offer customised problem solutions for both industrial and scientific partners by utilising the possibilities we have in the fields of microscopy, mechanical testing, thermal analysis, rheology and spectroscopy.

To answer your questions on failure and damage analysis, data measurement and part testing, our members of staff have the necessary experience not only in materials science, but also in the processing of plastics, effects of external stresses on plastic products, instrumental analysis, quality management and the systematics of the procedures. All our material testers, technicians, engineers and scientists are qualified for this.

Our support and services are based on long-time experience in a wide range of different industries where our plastics and their products are used. The know-how acquired in practice combined with the theoretical knowledge provides the ideal basis for dealing with your problem.