Topic of the thesis:

Unidirectional thermoplastic tapes made of glass or carbon fibers are high-performance products that can be economically used in lightweight construction applications in high quantities. They can be used for local reinforcement of mechanically highly stressed areas in conventional injection-molded components. This can lead to significant improvements in the mechanical properties of structures while reducing the required amount of raw materials. However, the forming of complex laminate structures poses a major challenge. This forming behavior can be simulated in structural simulation programs. The realistic modeling of the material properties of the tape during forming is of central importance.

The thesis will be conducted in this research group:

In the Fiber-Reinforced Plastics/Dimensioning/CAE Methods research group, the mechanical properties of tapes are characterized and transferred into material models for numerical simulations. The findings of this work are particularly applied in the field of eco-friendly lightweight construction in the automotive and aerospace sectors.

Objective:

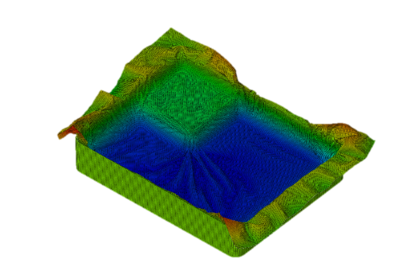

Development, simulation implementation, and calibration of a material model to describe the material properties of unidirectional thermoplastic tapes in forming processes.

For a bachelor's thesis, you will work on the following tasks:

- Research on material models of varying complexity

- Calibration of the models based on experimental data

- Conducting forming simulations

For a master's thesis, you will work on the following tasks:

- Research on material models of varying complexity

- Calibration of the models based on experimental data

- Conducting forming simulations

- Comparison of the quality of your simulation results with real components

- Deriving guidelines for conducting forming simulations

Your profile:

- Natural science-related degree program such as Mechanical Engineering, CES, Materials Science, etc.

- Motivated, careful, and independent working style

- Interest in structural simulation; prior knowledge is advantageous but not required

- Interest or prior knowledge in working with fiber-reinforced plastics is beneficial but not required

If you are interested in a thesis at IKV and in this or a similar topic, please contact me. We will discuss the specific scope and schedule individually.

Your contact person:

Martin Giersberg Sola, M.Sc.

Phone: +49 241 / 80 27271

Email: martin.giersberg@ikv.rwth-aachen.de