Topic of the thesis:

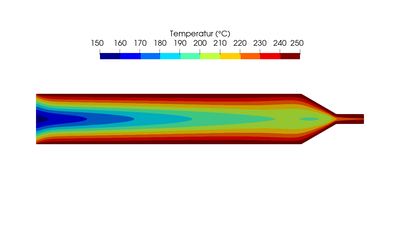

The maximum printing speed and thus the economic efficiency of commercial FDM 3D printers are no longer limited by maximum travel speeds. Instead, the melt capacity of the hot end poses a limit. Novel geometries of the flow channel in the print nozzle enable significantly higher heat input into the molten plastic. However, due to their microstructure, these geometries are particularly susceptible to structural failure.

The thesis will be written in this research group:

Within this project, new nozzle geometries for accelerated heat input have been designed using simulation methods. In the Dimensioning/CAE Methods research group, the results from flow simulations are used to determine the loads acting on the print nozzle.

Objective:

The aim of your thesis is to design complex geometries in the nozzle for maximum heat input and critical load cases using a simulation chain consisting of flow and structural simulations. Based on these results, you will derive design guidelines for the design of these nozzles.

For a bachelor's thesis, you will work on the following tasks:

- Determination of critical loads

- Setup of a structural simulation to demonstrate strength

- Simulation-based optimization of geometry and derivation of design guidelines

For a master's thesis, you will work on the following tasks:

- Determination of critical loads

- Setup of a structural simulation to demonstrate strength

- Simulation-based optimization of geometry and derivation of design guidelines

- Demonstration of strength on a real component

- Determination of the actual melt capacity of the optimized nozzle

Your profile:

- Natural sciences degree program such as Mechanical Engineering, CES, Materials Science, etc.

- Motivated, careful, and independent work style

- Interest in additive manufacturing; prior knowledge is advantageous but not required

- Prior knowledge in structural simulation is advantageous

- Enjoy pushing the boundaries of 3D printers

If you are interested in a thesis at IKV and in this or a similar topic, please contact me. The exact scope and schedule will be individually coordinated.

Your contact person:

Martin Giersberg Sola, M.Sc.

Phone: +49 241 / 80 27271

Email: martin.giersberg@ikv.rwth-aachen.de