Determining the damping behaviour

Problem: Determining the damping behaviour of bearing materials

In the drive train of ship shafts, which can be classified in terms of size between motor yacht, cruise ship and icebreaker, there are water-lubricated bearing solutions based on thermoplastic polyurethane (TPU) (Fig. 1), a material that is largely new for this application. Typically, these materials are manufactured by casting or injection moulding.

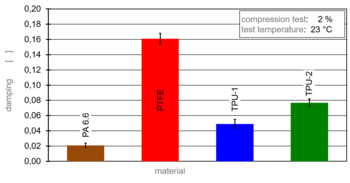

In order to be able to classify how the ship's shaft behaves in heavy seas, the damping properties of the TPU material are determined. For better classification, materials with properties known for the application are included (e.g. PTFE, PA 6.6).

Method: cyclic compression tests on the hydropulser

- Removal of cylindrical test specimens from bearings

- Dynamic-mechanical analysis to classify the temperature application range on the TPU material

- Determination of the damping properties at different compression levels under dynamic cyclic pressure-threshold loading

- Illustration of the real cases: normal sea state with 1 % compression, heavy sea state with 2 % compression

- Comparison of the damping capacity of the materials

Result: Broad spectrum of damping properties recorded

In the final result, all examined TPU materials show damping between 0.02 < tan d < 0.16 in the value spectrum spanned for the PTFE and PA 6.6. It is advantageous to evaluate the highest possible damping, which sensibly absorbs ("cushions") the impacting energy in the form of shocks on the shaft and converts it into heat. In this way, materials can be selected in future on the basis of the properties determined to suit the respective function.

Any questions?

![Shipping [Polarstern: Alfred Wegener Institute Helmholtz Centre for Polar and Marine Research] and hull with drive shaft](https://www.ikv-aachen.de/fileadmin/_processed_/f/4/csm_IKV-KAP-practical-example-damping-behaviour-Teaser_5fa6bd1545.png)