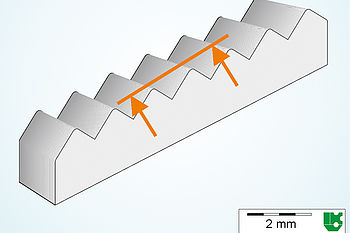

Injection-moulded gear racks made of POM

Problem: Reduced strength properties of POM gear racks

Injection-moulded gear racks made of polyoxymethylene (POM) are subjected to heavy mechanical loads, especially in the area of the tooth flanks due to interaction with the cogwheel. Customer complaints reported early failure of gear rack elements in which teeth break off during use. Appropriate tests are to be carried out to identify the causes.

Methodology: Microscopic structure analysis of the gear racks

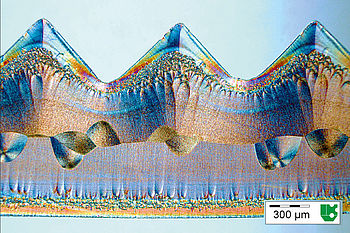

- Microtome sections at room temperature on the rotary microtome

- Structural examination using polarised transmitted light

Result: Cold edge layers in the part

The thin-section tests provide information on the homogeneity of the crystalline superstructures over the wall thickness. In this particular case, finely crystalline, so-called "cold" edge layers were observed, especially in the tooth area subjected to the most stress. POM reacts very sensitively if the temperature of the melt or mould is too low. The problem is that the melt then solidifies immediately it makes contact with the wall of the mould and does not have enough time to form spherulites. The geometry further encourages this through a larger contact area with the mould (rapid withdrawal of heat in the tooth area). Experience has shown that such edge layers are far more brittle than the core material, which had far more time to cool down from the molten state. The solution was to raise the temperature of the mould because the spherulites then have time to grow due to the slower cooling.

Any questions?

Christoph Zekorn

Microscopic analysis Head of the Microscopic Analysis Laboratory +49 241 80-28341 christoph.zekorn@ikv.rwth-aachen.deDo you have any questions on the subject of microscopy? Then phone us or send a message.