Material selection for fixing systems

Problem: Material selection with regard to predicting service life

External influences such as temperature, atmospheric oxygen and UV radiation all exert a load on plastics components that initially impairs their performance but subsequently leads to failure. For use in outdoor applications, the material must therefore be adequately stabilised.

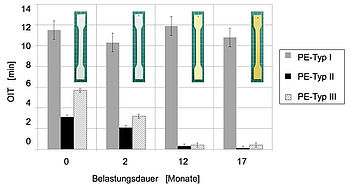

For selecting a plastic material for an outdoor fixing system (without direct UV radiation), the long-term behaviour of three polyethylene types ("I" to "III") is to be determined.

Methodology: Material analysis after accelerated ageing

- Accelerated ageing through thermo-oxidative loading at elevated temperatures in atmospheric oxygen

- Recording the resistance to oxygen with the aid of residual stabilisation via the oxidation induction time (OIT)

- Identifying the material damage through oxidation by means of infrared spectroscopy analysis

- Determining the mechanical failure characteristics via the elasticity modulus, tensile stress at yield and elongation (tensile tests)

Result: considerable deviations with regard to service life

Two materials show a strong dependency of the OIT on ageing time.

Material "I" shows, through virtually constant oxidation induction times, an unchanged structure and good mechanical properties, pointing to a long expected service life. Types "II" and "III", on the other hand, will age early as is shown by low stabilisation (declining OITs) and subsequent material damage by oxidation (by means of IR) and embrittlement (tensile test).

It was thus possible to select a suitable material through this simple combination of thermal, spectroscopic and mechanical tests.

>> Show all practical examples in the overview

Any questions?