The joint research project undertaken by AZL (Aachen Centre for Integrative Lightweight Design), IKV, and a number of partners from industry will reach its conclusion in September 2019. The outcome of the project is an integrative, self-regulating production system for the large-volume manufacture of structural components of fibre-reinforced plastics (FRP). The project has been financed over a period of three years by Germany's Federal Ministry of Education and Research (BMBF).

This production system combines the direct preforming processes of 3D fibre spraying and towpreg placement with a high-pressure RTM process. It is able to evaluate the influence of any process fluctuations on the component quality and – for the first time – to take corrective measures on its own. A further positive effect is the significant reduction of production-related scrap, which can lead to a significant fall in the final part costs compared with a textile-based production chain.

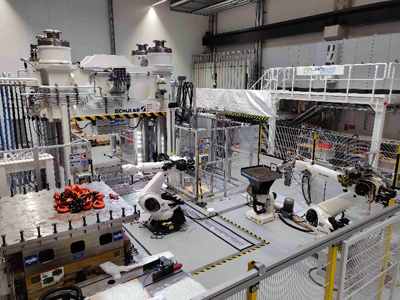

The research team will demonstrate essential aspects of the research project live at the concluding event on 19 September 2019 in the AZL pilot plant.

Other items on the agenda will include a presentation of the project and its overall results, a demonstration on reducing production-related scrap, and a presentation of intelligent production systems in everyday industrial practice. There will also be an opportunity to visit the AZL and IKV laboratories and pilot plants.

IKV, AZL and all project partners extend a cordial invitation to attend this open event at the AZL on 19 September.